All Types of Scrubbers and Industrial Dust Collectors

AIR COOLING UNITS

The basic principle of HANDLAIR air cooling unit / air washer units is that the taken in and filtered for its particulate matter by suitably designed filters. The fresh, filtered air is then made to pass through specially designed honeycomb structure of cellulose paper fills media, which has water absorbing properties. The air when passes through the fill media, absorbs the water and loses heat in the process. This makes air cool, which when supplied to the work area, provides comfortable conditions inside the work area. These units are available with capacity varying from 2500 cu.meter per hour to 2,00,000 cu.mtr/hr with combinations of single and multiple blowers. Air cooling units are also manufactured with spray type cooling sections, as per customer requirements. The unit chamber is normally fabricated with standard G.P. Sheet and powder coated for longer life. These are available in single skin as well as in double skin construction.

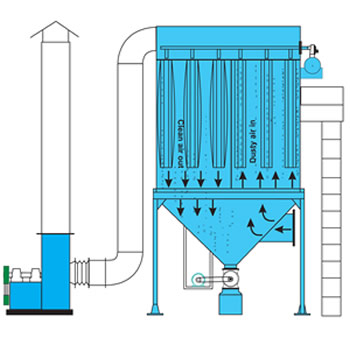

BAG FILTER DUST COLLECTOR

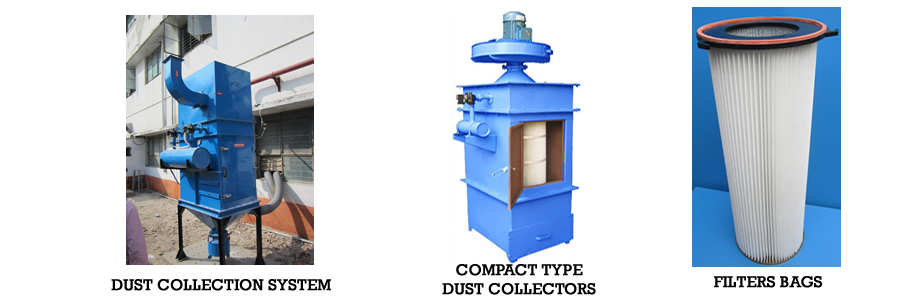

HANDLAIR make Bag filter type dust collector is a reliable and economical unit with high efficiency, widely used for metal grinding, polishing, buffing, mixing etc. These units are also widely used in tablet making machines, tea and food industries. These units are provided with high efficiency filter bags, in polyester /poly propylene needle felt media in plain as well as pleated construction. The capacity of these units varies from 500 cu. meter per hr to 50000 cu. meter per hour. The filter bags are cleaned with a pulse of compressed air which is initiated by electronic timer and a series of solenoid valves.

HANDLAIR Bag Filter type dust collectors are widely used to collect dust particles from the generating points, which in turn prevents the dust particles spreading in the hall. These types of dust collectors are used in a variety of industries, viz: pharmaceuticals, automobiles, transfer points, mixing plants, silos etc.

Principle:- The dust laden air is sucked from the generating point through suction hoods and ducts and made to pass through the bag house (filter section) where the air is filtered through the bags and the clean air is getting exhausted to the atmosphere through the blower. The dust particles accumulated on the surface of the filter bags are cleaned either by purging compressed air, or by a motorized shaking, or by a manual shaking mechanism. In the compressed air mechanism, the compressed air from an air tank is purged to individual filter bags through piping network intermittently with the solenoid valves and electronic timer. During normal dust collection process, dusty air flows through the filter and solid layer of dust forms on the filter surface. A quick bust of compressed air is shot through the filter media in the opposite direction of the dusty air stream, knocks the accumulated dust, which then falls in to bottom hopper. The accumulated dust particles in the bottom hoper is either collected in a dust bin or discharged to a conveyorised network through rotary air lock.

The different types of filters used are as under

(1) Pleated type, (2) Cartridge type, (3) Non Woven type.

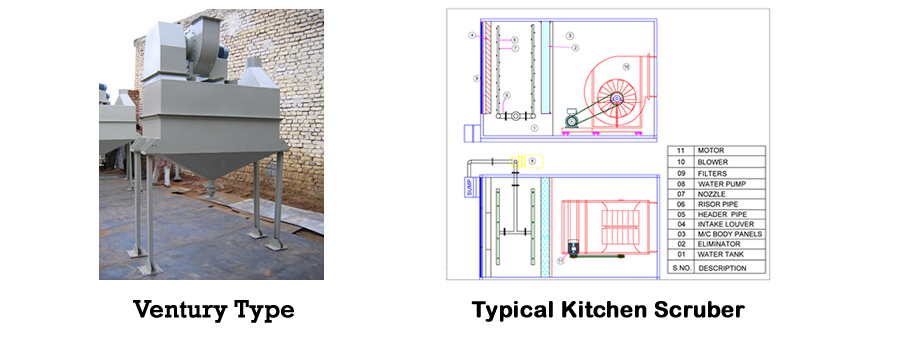

WET SCRUBBER

HANDLAIR wet type dust collectors are used for a variety of applications. The venturi type scrubbers do not require a water circulating pump, and are widely used for collection of coarse dust, where the dust settles in water without getting solved. These are normally installed in coal handling plant and ceramic industries. Spray type scrubbers are ideal for fume exhaust and are widely used for industrial fume exhaust applications as well as for commercial kitchen exhaust.

CYCLONE DUST COLLECTORS

HANDLAIR Cyclone type dust collectors named after the weather phenomenon are large tunnel shaped metal tube connected to ducts often used in a large variety of industries, where , the emission level requirements are not stringent. These types of units are also used before bag filter type dust collectors as pre collectors, where, the dust generation is quite high and emission levels are restricted.

Principle

Dust particles are sucked in at the top side. Air containing fine dust, blows out while the chips and large dust particles fall out through the bottom in to a drum or a screw conveyor. Blown out five Dusty air is filtered again, using media filtration or wet scrubber as per requirement.

These are generally used in, Foundries, Metal spraying, Pneumatic conveying, Cement Industries, Food Processing, Zinc Spraying, Recycling, Powder coating, Shot blasting, Wood working, Pharmaceuticals,Transfer points, etc.

HANDLAIR cyclone type dust collectors are widely used for a variety of applications like grinding, polishing, buffing machines etc. The capacity of these units ranges from 300 cu.mtr/Hr to 50000 cu.mtr/Hr. In single as well as in multiple units.

HANDLAIR unit type dust collectors comprises of compact dust collectors complete with centrifugal blower, its driven motor, dust collection bin and supporting frame work. These units can be supplied either in mild steel or stainless steel construction as per requirement.

These dust collectors are ideal for using with a wide range of applications like grinding, polishing, buffing operations etc.